Wind turbine blade inspection and repair

The monitoring and maintenance of wind turbine blades are essential for the safety, good operation and profitability of installations.

We offer specific service contracts on inspection

and blade maintenance or à la carte services.

We quickly deliver quality intervention reports using our database tool, which also allows us

qualitative monitoring of interventions and damage.

For more information, contact us !

In order to carry out periodic monitoring and to respond to the ICPE Decree of June 22, 2020, we carry out soil inspections using a powerful

telephoto lens to ensure that there is no critical damage to the blades and thus allow

safe operation of the wind turbine.

Our database tool allows us a qualitative follow-up of the evolution of

damage over time to establish a true health check of the blades.

Clear recommendations are given on the actions to be implemented and

allow the planning of necessary repairs.

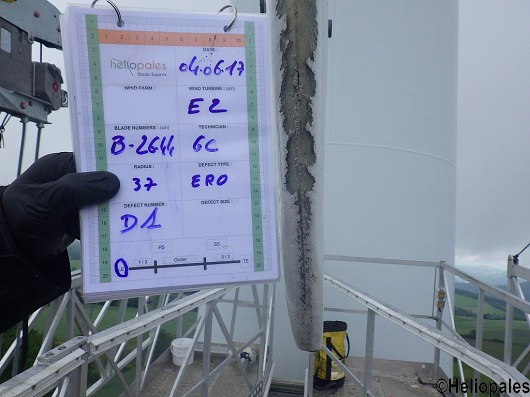

Indispensable complement to follow-up inspections, internal inspections and

external blades make it possible to establish a conformity check and a health check.

We offer visual inspections of proximity of the blades adapted to

each stage of the wind turbine's life: assembly, end of warranty and maintenance contract, due diligence, damage assessment.

The unblocking of the water evacuation drains and the resistance measurement of the surge arrester system are carried out

during each intervention.

Depending on the characteristics of each project,

we intervene using the most suitable means of access: suspended mobile platforms, PEMP or means of access on ropes.

The maintenance and protection of the leading edge (LEP) is an issue

important for the proper functioning of the wind turbine. The application of a specific protective paint

leading edge optimizes the service life and effectiveness of long-term protection.

Targeted repair of surface damage and periodic campaigns

preventive maintenance allow the blades to be kept in good general condition and to optimize the costs of

maintenance.

Unclogging of water evacuation drains, control and measurement of resistance of the surge arrester system.

Major cracks or lightning damage, we carry out structural repairs

necessary to allow the operation of wind turbines in complete safety.

We operate in compliance with O&M standards for the repair of wind turbine blades and

bring general conditions of warranty of 2 years.

In the air, on the ground or in the workshop, we carry out the necessary repairs

to restore all the damaged structures and allow the blades to return to operation.

On the Hauts de France, we store and repair in the workshop the blades that have been replaced and

for which there is sometimes a real economic interest in considering refurbishment.